The Ultimate Guide to Increasing Life-span: Undercarriage Parts Upkeep Made Easy

Take Full Advantage Of Performance With Resilient Undercarriage Components

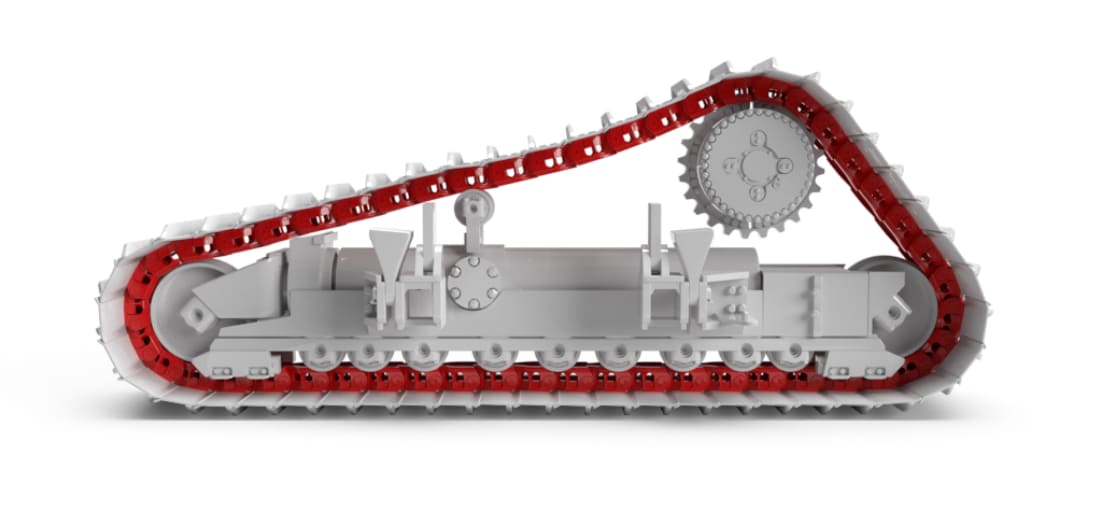

In the realm of heavy equipment and tools, the function of undercarriage components is extremely important in making certain ideal efficiency and long life. The performance and efficiency of these parts can considerably affect the overall procedure of equipment, making the option of resilient undercarriage parts a crucial decision for operators and managers alike.

Benefits of Making Use Of Resilient Undercarriage Parts

Using sturdy undercarriage parts not only boosts the durability of heavy equipment yet likewise decreases upkeep expenses considerably. By purchasing high-grade undercarriage components, such as tracks, sprockets, rollers, and idlers, tools drivers can experience enhanced uptime and improved total performance.

Furthermore, the longevity of hefty machinery is directly connected to the high quality of its undercarriage parts. Long lasting elements can endure the rigors of requiring applications, ensuring that the devices continues to be functional for extensive periods. As an outcome, drivers can avoid pricey downtime and maintenance expenditures, eventually maximizing the roi for their machinery.

Elements Impacting Undercarriage Resilience

The resilience of undercarriage parts in heavy equipment is affected by different vital aspects that straight influence performance and long life. One of the key elements influencing undercarriage longevity is the quality of materials made use of in manufacturing. High-grade products, such as hard steel, are crucial for withstanding the severe conditions and heavy lots that undercarriage components go through. Appropriate upkeep practices also play a vital role in determining the life-span of undercarriage parts. Normal examinations, lubrication, and timely replacement of worn-out components can significantly expand the sturdiness of the undercarriage.

In addition, environmental variables can have a significant impact on the longevity of undercarriage components. Direct exposure to unpleasant products, extreme temperature levels, and harsh working conditions can increase deterioration on undercarriage elements. As a result, picking undercarriage parts that are especially designed to endure these environmental difficulties is vital for making certain resilience.

Additionally, the style and design of undercarriage components have a straight influence on their resilience. Components that are developed to distribute tons evenly, decrease rubbing, and decrease anxiety concentrations are a lot more most likely to have a longer life-span - undercarriage parts. By thinking about these important elements, equipment drivers can optimize the durability and efficiency of their undercarriage components

Upkeep Tips for Prolonging Undercarriage Life

Implementing routine maintenance regimens is necessary for prolonging the life-span of undercarriage parts in hefty machinery. To extend the undercarriage life, it is critical to often check for wear and tear. Consistently examine for loosened or absent bolts, damaged rollers, or misaligned tracks, as these issues can rise and trigger additional damage if not addressed promptly. Furthermore, make certain that the undercarriage is appropriately oiled according to manufacturer guidelines to lower rubbing and stop early wear.

An additional vital maintenance tip is to keep the undercarriage tidy from dust, rocks, and particles. Accumulation in the undercarriage can speed up wear and rust, bring about pricey repair work. Washing the undercarriage after operation in rough conditions is recommended to look these up prevent these concerns.

Last but not least, monitoring and recording maintenance tasks can assist in producing an aggressive upkeep schedule. Maintaining thorough records of repair services, examinations, and replacements can offer useful understandings into the undercarriage's problem and performance with time, assisting in anticipating and avoiding potential failings. By adhering to these upkeep pointers vigilantly, operators can considerably increase the sturdiness and performance of undercarriage components in hefty equipment.

Choosing the Right Undercarriage Components

Selecting appropriate undercarriage components is crucial for optimizing the performance and durability of hefty machinery. When it comes to picking the best undercarriage elements, there are several factors to think about.

Choosing for respectable brands understood for creating high-performance and long lasting undercarriage parts can considerably impact the overall efficiency and durability of the machinery. By thoroughly choosing the best undercarriage components, tools owners can improve productivity, lower downtime, and prolong the lifespan of their hefty machinery.

Case Studies: Improved Performance With Resilient Components

Including durable undercarriage parts has actually demonstrated significant enhancements in equipment efficiency. One study included a construction firm that upgraded its excavator's undercarriage elements to extra resilient alternatives. The company observed a significant decline in downtime due to undercarriage maintenance, leading to raised productivity and cost savings. The long lasting parts endured severe working conditions, reducing wear and tear dramatically.

In another circumstances, a mining operation changed the undercarriage components of its bulldozer with high-grade, long lasting choices. This button resulted in a remarkable enhancement in the excavator's maneuverability and overall efficiency. The machine could navigate tough surfaces much more effectively, leading to improved operational performance and decreased fuel usage.

Additionally, a logging company invested in durable undercarriage components for its forestry devices. These situation studies underscore the tangible advantages of making use of sturdy undercarriage parts in maximizing machinery web link efficiency and long life.

Final Thought

In verdict, using long lasting undercarriage components can substantially boost efficiency and durability of hefty machinery. Case researches have actually shown that spending in long lasting undercarriage parts can lead to enhanced overall efficiency and efficiency in different industries.

The performance and efficiency of these components can dramatically influence the general procedure of equipment, making the option his explanation of resilient undercarriage components a crucial choice for drivers and managers alike.Integrating long lasting undercarriage components has shown considerable enhancements in machinery performance. These case research studies underscore the tangible benefits of utilizing sturdy undercarriage parts in maximizing equipment performance and longevity.

In conclusion, making use of durable undercarriage parts can substantially boost efficiency and longevity of heavy equipment (undercarriage parts). Situation research studies have revealed that spending in durable undercarriage components can lead to boosted overall efficiency and productivity in numerous markets